Imitha enye ezintathu 8-itshaneli ezizodwa-ezimile umatshini sanding

Ulwazi olusisiseko.

| imodeli | Imitha enye ezintathu ezisibhozo | Inkonzo yasemva kokuthengisa | kwi-intanethi |

| umbala | Intsimbi engwevu | uphawu lwentengiso | Tenglong |

| Indawo yosetyenziso | Ucango lweKhabhinethi/ucango lwamaplanga | Yenzele okuthile | Yenzele okuthile |

| Iphakheji yezothutho | iinkuni | Iwaranti | 1 unyaka |

| imvelaphi | eTshayina | Inqanaba elizenzekelayo | oluzenzekelayo |

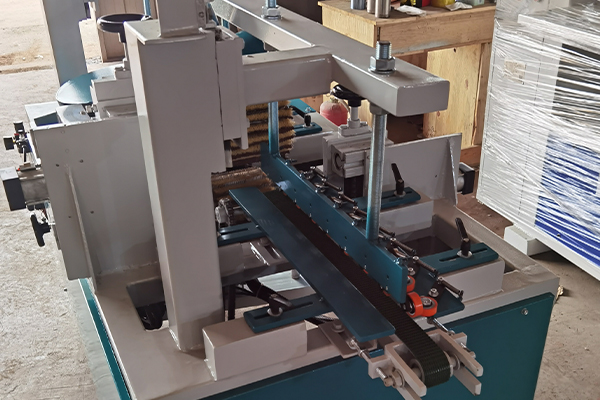

Ingcaciso yeMveliso

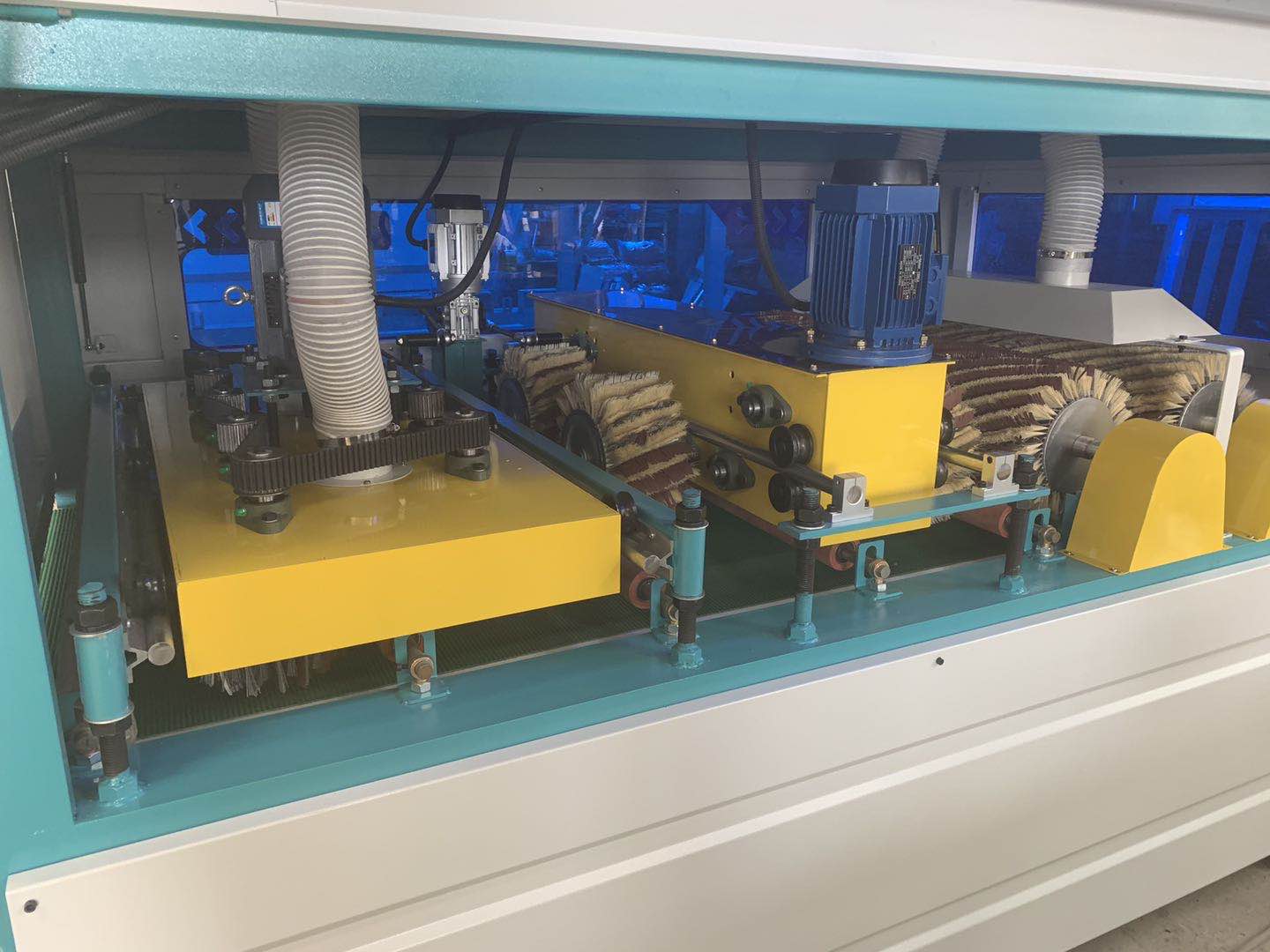

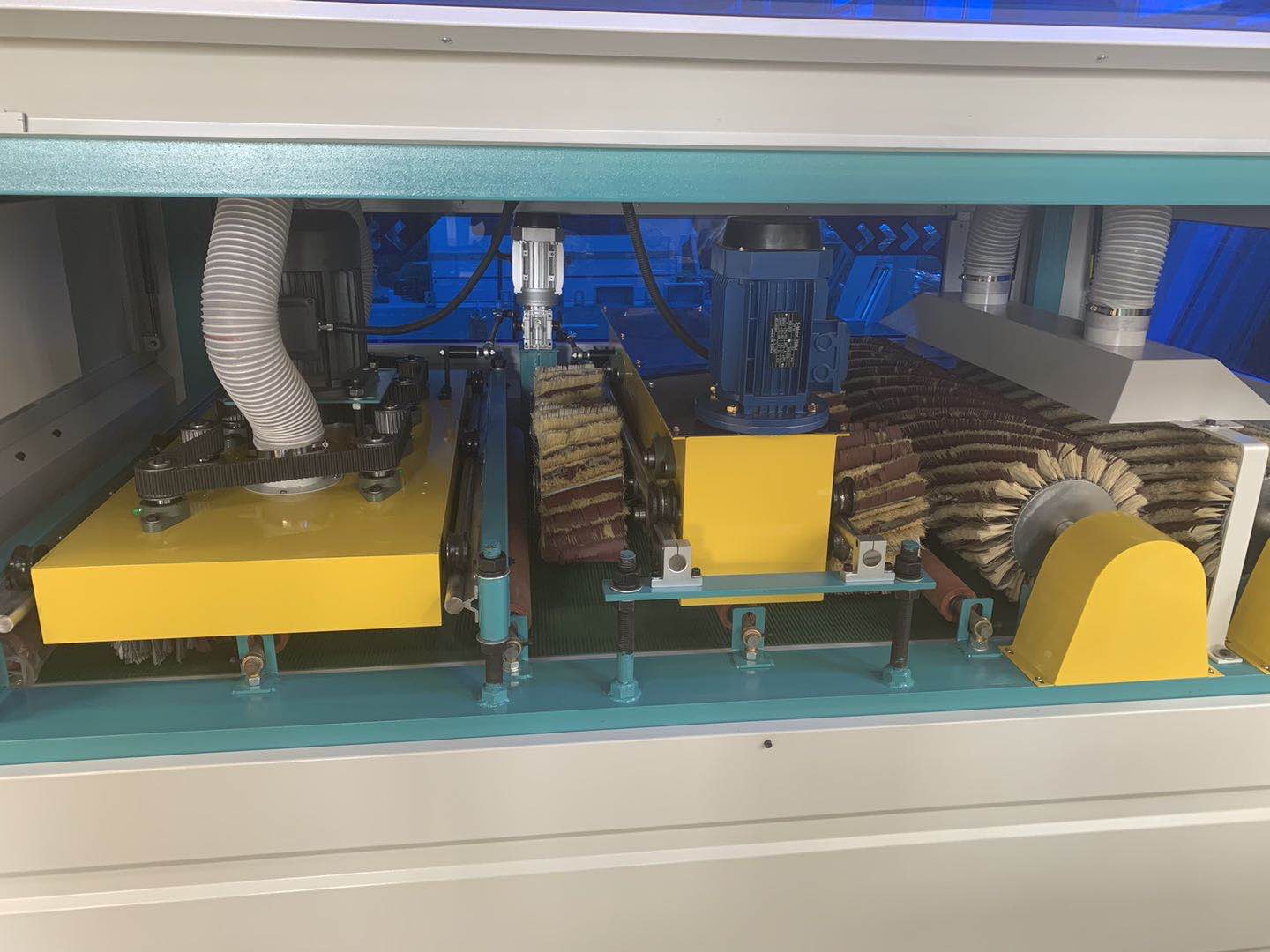

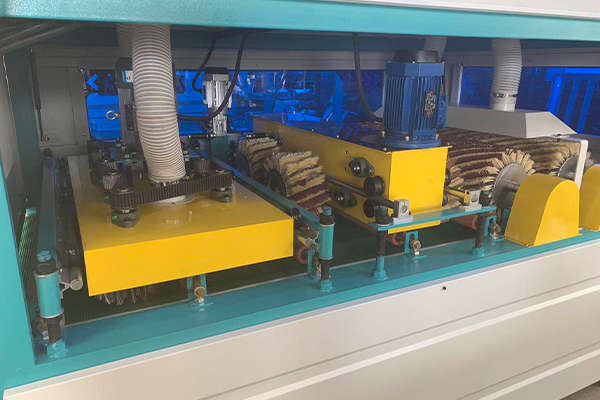

Isakhiwo esiphambili somatshini sidibaniso lwamabhanti abrasive kunye neentlobo ezahlukeneyo zokuqhawula kunye neebhulashi zokugaya.Isitishi ngasinye sinokusetyenziswa ngokuzimeleyo okanye ngokudibeneyo: ngasentla, sifanelekile kwiimveliso ezahlukeneyo kunye neenkqubo ezahlukeneyo ezifunwa yifektri.Ngokusetyenzwa, endaweni yomsebenzi osebenzayo wokupolisha ngesandla.Ukusebenzisa itekhnoloji yokulawula ibhanti ezinzileyo kunye nethembekileyo yelungelo elilodwa lomenzi wechiza, i-deburring kunye ne-chamfering inokugqitywa ngexesha elinye.Umsebenzi uyaphatheka kwaye uyaqondakala.Isixhobo sinomthombo wokukhanya we-LED eyakhelwe-ngaphakathi.Iqonga lokuhambisa ivacuum linokusetyenzwa ukuze kufunyanwe imisebenzi.Ukugaya kuguquguqukayo kwaye akonakalisi umphezulu we-workpiece.Umqokeleli wothuli olumanzi ngokuzikhethela angasetyenziselwa ukutshayela xa usebenza.

Iiparamitha zeMveliso

1. Iphaneli yokulawula ejikelezayo: Kulula kakhulu ukulawula umatshini.Isantya se-roller ezintandathu silawulwa ngabaguquli be-frequency ezintathu, kwaye isantya se-roller silawulwa ngokulula ngokutshintsha kwipaneli yokulawula.Abasebenzi banokuhlengahlengisa isantya ngokwezinto ezahlukeneyo.

2. I-Cross rollers: Iisethi ezimbini ze-cross rollers (i-9 iyonke) zijikeleza ngokuzimeleyo kwaye ziqhubele phambili ngexesha elifanayo ukuqinisekisa ukuba umphumo wokugaya umphezulu kunye ne-grooves enqamlezayo.

3. Iibhulashi zediski: Amaqela amabini eebhulashi zediski (i-9 iibrashi zediski zizonke) zijikeleza kwicala elichaseneyo, kwaye isantya se-roller siguqulwa rhoqo.Lo matshini unokuqonda ukungalingani kunye nokusila komphetho wee-engile ezahlukeneyo ngokuhamba kweplate ngokwayo kunye nokujikeleza kwe-disc brush.

4. I-Longitudinal rollers: Iiseti ezimbini ze-brush rollers ezide zijikeleza ngeendlela ezichaseneyo, ezinokunyuswa kwaye zithotywe ngokuzimeleyo ukuze kuqinisekiswe ukuba i-omnidirectional surface rough kunye ne-R angle polishing effect.

5. Kufanelekile ukubunjwa kunye nokugaya okucokisekileyo kwezinto ezenziwe nge-laminated, iibhodi ezidibeneyo, iibhodi zeeplanga, iinkuni eziqinileyo, ifenitshala yepaneli, imigangatho ye-bamboo, iingcango zokhuni, njl.Kwaye ukwenziwa kwefenitshala.

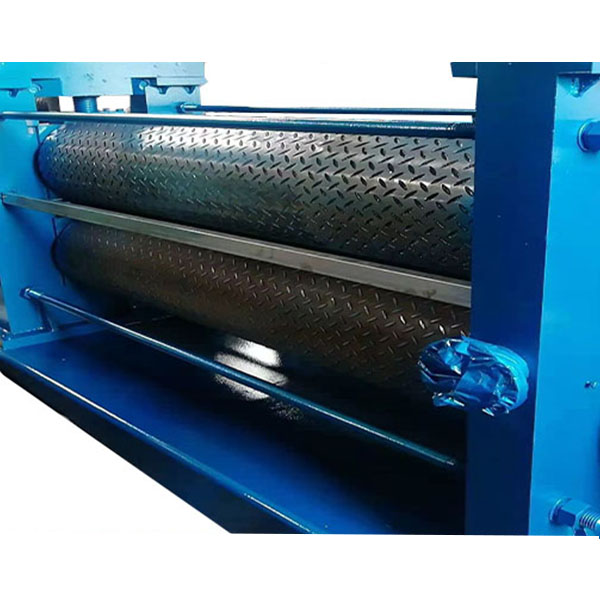

6. Uhlobo lwe-R-RP: i-roller yokuqala yintsimbi yensimbi;iyunithi yesibini yi-85 ° rola yerabha kunye nephedi yesanti yomoya.Uhlobo lwe-RP-P: Iyunithi yokuqala i-rubber roller ene-sand pad;iyunithi yesibini yiphedi yesanti yomoya.

Iirola zentsimbi zisetyenziselwa ukulungelelanisa kunye nokupolisha, kwaye iiroli zerabha zisetyenziselwa ukupolisha kakuhle.

7. Isixhobo sokukhusela i-roller yoxinzelelo sigcina ipleyiti kwitafile yokutya ukuze kuqinisekiswe ukhuseleko lomsebenzisi.

Iifoto ezineenkcukacha